Cox Medallion .051 NFFS Special

|

Disclaimer: *Veco is a trademarked name belonging to MECOA. I hope everyone is happy now... The Veco™ Series 100 engines (.19, .29 & .35) are a great choice for free flight Nostalgia Gas. The Series 100 is legal in all their forms, including the .29S and .35C, plus the ubiquitous .19, they do well in each of their classes. The .19 sized Veco™ was tested, along with the OS Max MkII and MkIII, and found that either was far superior to any of the many old Greenheads we've used in Nostalgia comptetion over the past decade and a half. Either the OS or the Veco™ is definitely the better choice over the GH motors. Note: I'm no longer doing engine work, but am leaving the page for reference. I recommend Bob Mattes at flyfreeflight.com Bob is expert in every detail about getting the most out of my favorite Veco Series 100's and OS Max's, too. Does wonders with the Tee Dee 020. Wonderful site where you can learn a lot. Specific pricing. Custom heads for Nelson plugs in the Veco and OS plus one for insert plugs in the .02. Custom rods, more. Tell Bob I said hello. |

||

|

Here's the current iteration of the continuing evolution of work with the Series 100 .19. Shown here is the combined engine back-plate mount with internal fuel passage, fuel shut-off, fuel filler, bladder, etc. |

These modifications really made a serious improvement to an already strong running engine. By themselves, they won't help; The first order of business for a strong running engine is a set of excellent fits. NOTE: Though these modifications may seem to be extensive, the timing on this example has not been altered. What might not be evident here is that the sleeve started life as a Series 100 R/C sleeve. The timing is the same as the FF/CL version, but the exhaust & bypass is smaller. This liner has had the bypass opened to the same specs as the CL version, and the stock exhaust of the R/C version left alone. |

"Stage II" bypass modification to a FF/UC sleeve with the rectangular bypass cut into the R/C sleeve. Shown here prior to any blending/tapering as in the photo left. |

|

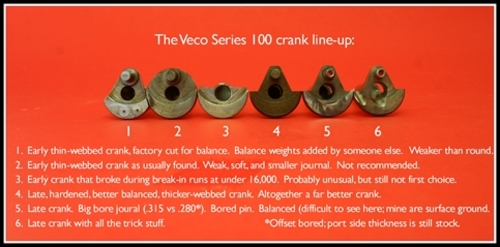

I've found several different cranks in the Series 100 engines. There's only one that's good for high performance use in my opinion. |

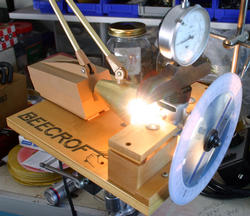

One of the special jigs; this one used to hold a sleeve for cutting both a UC/FF bypass, and Stage II sub-bypasses into an R/C sleeve. |

|

|

Hm, what do we have here? Guesses to Bob@TheAeroSmith.com |

Dick Zachman's Stage I done up in 'Greenhead' attire. Dick's motor uses the excellent MECOA needle valve assembly #7738 . |

Custom engine work gets custom box and insert. |

|

Gene Christensen's Stage I. Here you can see a custom venturi fit in place of the cut-off one as they came in the R/C version of the motor. You can see the nice little button of JB Weld that's blocking the other side of the NV. |

And another custom engine and custom box. This engine will use a remote needle valve. |

TheAeroSmith's logo stamp, placed discreetly. Actual size is .125 OD |

|

TheAeroSmith way to protecting your Nostalgia Series 100 while using a starter motor. |

Together and ready for use. Note here MECOA's excellent needle valve assembly; Their part number 7738. |

Oh, Man! What now? |

|

A little relief in the rear, and.... |

And...tah-dah...the everlasting answer to blown rear cover gaskets! Simple, small O-ring arrangement. The inside cover has an O-ring groove machined in it.

More photos coming soon: If you have photos I can use here, drop me a line. |

Stage I Series 100 for Bob Sowder. A NV I don't care for...stock! Bob's ordered the MECOA 7738 assembly for it. |

|

This needs a better spot - time for some rearrangement. In the meantime, here is a Series 100 cast head grafted to a modified K&B combustion chamber; What's REALLY cool here, is that I found a really true-to-the-original green as found on the Greenhead engines! |

Modified OS .10 R/C needle valve assembly. The metric threads have been turned down, and the a collar silver soldered in its place; then threaded SAE. The little nut is made from ¼" hex stock. These make an excellent remote NV. |

In one of the photos above you can see a custom venturi fit in place of the cut-off one as they came in the R/C version of the motor. You can see the nice little button of JB Weld that's blocking the other side of the NV. |

|

|

"In stock" Series 100 .19's here. Good thing this is a hobby and not a business! |

Gunmetal blue custom .21 Series 100. Was an R/C version. Fitted with new venturi. Ted Hidinger's. |

|

Always custom boxed in clear crystal container. |

One of the engines above started its new life from this sad looking motor. |

Used on box insert for Ted Hidinger's engine. |

|

NOW OUT OF DATE! The timing check arrangement. Lamp shines inside rear, making it easy to spot precisely where ports/bypass open and close. |

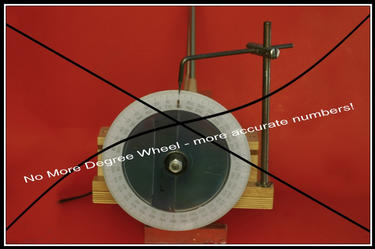

I'm scrapping the degree wheel in favor of some depth measurements and a few calculations. Copy and paste: http://doov.com/cgi-bin/tgc_timing.cgi |

More to follow regarding piston location to determine the traditional 'numbers' for port, bypass & exhaust timing. Seems to generate much more accurate figures than the traditional degree wheel method. I use this: http://doov.com/cgi-bin/tgc_timing.cgi Sorry, you'll have to copy and paste it, but it's great stuff. |