Cox Medallion .051 NFFS Special

|

Presented here, taken from NFFS' Freeflight Digest magazine. (Written by Bob Beecroft) |

|

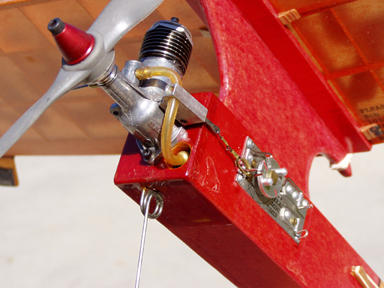

Tiny Half-A gas, Early Nostalgia FUBAR. Screaming OK Cub (for real, a screamer!) Pressure Fuel Systems: From a letter to a friend who asked... I have been using some sort of pressure feed system in nearly everything for an awfully long time. It adds not one "R" but it does make for steady, solid engine runs and more responsive needle valve adjustments...assuming the pilot is paying attention. (I wasn't at a recent contest!) One DOES have to pay attention to things like ensuring the needle adjustment will stay put. Is the lock nut snug on the split collar? Mine nearly fell off on a new NV assembly in the engine. Ran fine on the ground & for a quick test flight, but then the engine went very rich about 4-5 seconds out on a full run on an official. Dumb move. Lucky though: had the engine gone lean it probably would have been the end of a good one. Pay attention! I don't even use suction feed on my stunt U/C... the 'uniflo' tank arrangement works wonderfully there. It isn't really pressure, but it does make the motor run much more steadily than straight "suction" (really, atmospheric pressure) feed. With suction feed, the engine gets its fuel from creating a slight vacuum at the venturi. That slight pressure differential between 15 or so psi normal sea-level pressure on the tank, forces fuel from the tank to the engine's venturi which is at a lower pressure. Engines that create very little differential (ones with very large intakes for their displacement) won't even run without some kind of (external) pressure system, like a bladder, crankcase or muffler pressure. What do I use for pressure? Actually, I currently have models with no less than four slightly different arrangements. They differ only in that I use pacifiers, latex tube, toy balloons (the kind used to make animals and such - the long skinny ones) and some great neoprene tubing. The neoprene is the best of all these for anything bigger than 1/2 A's in my opinion. Pacifiers - Binky's are great. They are fine for bigger, modern, engines like ABC 15's and up. I have used them with great success for many years as have many others. I recommend blowing them up with air (use a syringe) and "massaging" them a bit so they blow up evenly. They have a tendency to blow out a sidewall, so to speak, causing one area to do all the work and creating a weak spot, besides. By breaking them in this way (massaging them) it assures the pacifier will have a longer life and you will have more fun, unless you like a good drenching in nitro, alky and oil. At least that's one opinion. Neoprene - just super for larger engines - anything, say .15 and up. Working great for me on NOS gas motors, Nelsons, other high performance engines. It is black, .030 thick X .250 diameter. Appears much the same as the old, real, pen bladders, but in tube form. I'm working on a source for this.(See note 1) These seem to last a good, long, time. Seems to be little affected by the fuel. Requires no massaging to break them in, they just blow up and look like a big, black, smooth sausage. I simply tie an overhand knot in the tube, cut off about 1 1/2 inches or so, put the open end over an automotive 1/4" vacuum fitting, then wrap a DT band a bunch of times tight as I can get it. (This applies to any of these pressure delivery vessels - I use the same fittings and binding method for them all.) Sure, soft wire works fine, also. See note 2) Now it's ready. Just fit up some surgical tubing (or the new silicone whitish stuff that Hank Nystrom (See note 3) sells) to go to the pinch-off and on to the engine, and you're ready. Hank sells some great fittings, too, intended for medical use. Order up a dozen and you'll be set for life. I like the auto fittings too, as they come in quite a number of styles so you can take your pick. See Pep Boys and the like. Surgical tube: I have used the 3/16" OD. It blows up to about 3/4" and just gets longer with more fuel (assuming there is enough tube length provided.) If you try to put in more fuel than there is tube length the pressure goes up exponentially for a bit, then it explodes. I built a 'Duster with some real keen hollow cheeks. The one on the right side has an opening about the size of a fat hot-dog inside - holds about 50 or 60 cc's. About enough to get the K&B elephant motor running, tuned, and under way. They DO use a lot of fuel! I don't recommend latex tube for a bladder system. More pressure than you need or want. Toy balloons - Highly recommended for 1/2 A and the smaller engines. Despite rumors and strong opinions to the contrary, even reed-valve engines can handle these, and well, I might add. I use the long skinny ones, one inside another. The second one is to provide some protection for the fragile nature of the beast. You can use one of the skinny ones inside a slightly larger round balloon, too. That provides little or no additional pressure and acts to protect the bladder providing the fuel. These usually last long enough for an entire day's flying. An interesting note: Should the engine suddenly need the NV opened up a bit before launch....the engine is telling you that one of the balloons has broken and there has been a pressure drop. Balloons are fragile. Adjust, launch and take your chances - or better, listen to what it's telling you; shut it off, and replace them. Experience speaking here. Actually, ALL these bladder types are fragile, especially if left exposed (outside the fuselage). Another side note: The biggest property damage insurance claim AMA has ever had to pay was caused by a freeflight model landing on power lines and causing a fire. May have been an aluminum clad model caused a short and a shower of sparks, and nothing to do with a fuel system. But just think how much more likely a fire could be sparked and spread should a model DT and burst an exposed pacifier...maybe just what a fuse equipped model needs to start a fire where otherwise one may not have started. I prefer to place the pressure bladder inside the fuselage, rather than flapping around in the breeze outside. An interior location is not much of a problem except for a few high-thrustline designs. (To make it easier there, a good old hard-tank and crankcase pressure works well. Really does elsewhere, too, but I like the simplicity of the bladder system.) I normally use one of the compartments formed by the fuselage formers near the front for the pacifier enclosure. I usually put a former/bulkhead close behind the firewall, then another spaced behind it far enough to use for the bladder compartment. A 3/8"-1/2" hole in the bottom-center of the compartment is the access. When the fuselage is complete, except for finishing details - say the final fuel-proofing - I mix up about an ounce of (the now old) K&B SuperPoxy clear (color may be just as good) and simply pour it into the compartment. (Be sure to make it snug all around so this stuff doesn't end up pouring out the tail!) Slosh it around in there for a minute or so, then drain it back into the mixing cup. Come back in 20 minutes or so two or three times and repeat the process. I have a fuselage from a C ship that was built in 1974 that had its share of drenchings with 70% nitro. Never flushed it out with anything. When I got back into this about twenty or so years ago, it was resurrected, flown, finally broken for good. I bandsawed the fuselage apart lengthwise right through the firewall and pacifier compartment. There was not ANY seepage at all. Not the smallest bit of oil soak to be found. SuperPoxy works. I don't know about the new stuff. I have a lifetime supply of the old, and the shelf life seems to be about forever if kept sealed tightly. About shut-off systems with pressure: I have used flood-offs in the past. They can be used safely and effectively when done correctly. The pinch off cuts most engines cleanly and I prefer this method. Generally, the closer to the venturi you can pinch it, the cleaner the cutoff. I like a remote system off the timer. The setup that Bob Oppegard sold works great. It is now available from Hank Nystrom (See note 3). There are a number of simple ways to do it. I even have some built right into the engine mounts. Anyway, that's a little on pressure systems, as I know them at least. Hope there is something here you find of value. Bob Beecroft Bob@TheAeroSmith.com 3488 Linda Vista Terrace Fallbrook, CA 92028-9127 760-723-2499 |

|

|

Notes: 1) Black Neoprene tubing - contact me. Also, CoreHouse, 1249 Jill Drive, Hummelstown, PA 17036, catalog only a buck ($1). They have some good (red) stuff I have seen but not used. Same dimensions as the black, but I'm told it is Latex. Lots else, too. John Oldenkamp has been using the small red tubing with good results on 1/2A's. 10 feet and 10 fittings runs ( plus S&H). 2) Soft wire - Try a Michael's or other arts and crafts place. I like Westrim Crafts style 891G1 Gold (it's soft brass) Beading Wire. Also see 890S1 Silver Beading Wire. It's soft steel. They each come in 28 and 32 gage. Both solder wonderfully so have other applications for us, too. You don't want the good, braided beading wire in this application. 3) Tubing, fittings, pinch off device, lots of cool stuff - Hank Nystrom, Texas Timers 3317 Pine Timbers Drive, Johnson City, TN 37604 Phone 423-282-6423 e-mail: txtimer@tricon.net.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|